|

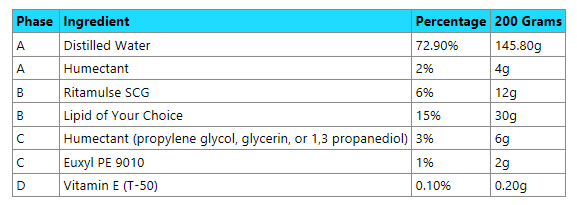

In this post, I will share how to formulate a STABLE natural body lotion. I will include some percentages which you can customize. Lotions, at their core, are three different ingredients—water, oil, and emulsifier. As you know, water and oil do not mix. They need something to aid in dispersing one into another. The emulsifier we will use today is Ritamulse SCG (INCI: Glyceryl Stearate, Ceteryl Alcohol, and Sodium Stearoyl Lactylate). This emulsifier is a complete emulsifier that can be used in a pH range of 5-7.5. The max oil phase you can have is 25%. It is suggested usage rate is 2-10%. I have found from doing real-time stability testing that It should be 6% or greater. In this formulation, I am going to be using 6%. For a body lotion, I include 15% of a lipid. This is where you can experiment. You can do all one lipid. You can blend lipids. You can only do vegetable oil. You can blend vegetable oils. You can include a liquid ester from 3-5%. You can include a butter to make a body butter. You have a ton of options! You need to be using a thermometer, but it is really important with butters to make sure that they are melted so that they do not become grainy. Looking like it is melted is not enough!!! For some hydration, I will include 5% of a humectant. Propylene Glycol, 1,3 Propanediol, Glycerin, Sodium Lactate 60% (change to 2%), Sodium PCA, etc. Just like the oil, you can blend humectant too. My favorite combination is glycerin at 3% and 2% butylene glycol. You could also just use 5% glycerin. Completely up to you. For stability, I am including vitamin E and a preservative. If you use a different type of vitamin E (not tocopherol acetate, which is only for the skin), use the low end of the usage rate. Vitamin E will delay oxidation. The preservative kill and prevent microbial growth. I am going to use Euxyl PE 9010. It is considered naturally compliant. It is used at 1%. It is more oil-soluble than water-soluble, so it needs to be mixed with propylene glycol, glycerin, or 1,3 propanediol. I would use 3% of one of those as a solvent. If you do that, you can choose to use something different for the other 2% of the humectant. For the other 2%, it will not be used as a solvent, so that you can use any other one. If you would like to use another preservative, ensure it is compatible with all the other ingredients and the pH. Let’s look at the formulation. Calculations: 100-(2+6+15+3+1+0.10)=72.9 72.9*2=145.8 Method: Sanitize all your equipment, containers, and workspace. Gather all your ingredients and make sure that your notebook is set up. In a glass beaker, add all your phase A ingredients. Stir until the ingredients are uniform. Weight the phase A beaker. We will need this weight later. Get a smaller beaker at add 10-20 grams of distilled water. This water will be used to compensate for evaporation during heating. Weigh out your phase B ingredients in a separate beaker. Create a water bath. Ensure that the water is high enough that both the water and oil are submerged in the water. Heat both phases and the extra distilled water to 70 degrees C. Hold it for 20 minutes. After 20 minutes, Take the water phase off the heat. Protect your scale, as heat can mess with the scale. Weight the water phase and add additional water to the weight you had in the beginning. Note if you have a spatula or lab spoon. As if that was removed, your weight would be way off. Pour the water into the oil in a thin stream. Blend with a high-shear mixer such as a stick blender or homogenizer. If using a stick blender, blend for 5 minutes. If using a homogenizer, blend for minutes. The lotion will be very thin, so work up the blend. You do not want hot cream spraying everywhere. Allow the lotion to cool below 40 degrees C. While the product is cooling down, you can prepare phase C. In a glass prep cup, weigh out phase C and mix it. Once below 40 degrees C, add phase c and mix well. Then add phase D. Be sure to mix it in well. Use either the stick blender or homogenizer for a minute to get everything combined. I know it may seem like a waste but it is important for stability. Allow to come to room temperature. Pour into final packaging. Be sure to label and date your latest formulation. Congratulations, you have made a lotion! Adjusting pH: Adjusting pH (Dilution Method): Get two beakers; one will be used as our washing beaker, and the other will be used to make the dilutions. The main thing with making dilutions is you want to make enough that the probe can be covered. You can weigh out 1 gram of product and 9 grams of distilled water to make a 10% dilution. Or you can weigh out 2 grams of product and then 18 grams of distilled water. Get your pH meter out and rinse with distilled water into the other beaker I had you get. Dry off the meter with a lint-free product. Mix it well and take the pH. If you are using strips, do not make a diluted solution no matter the viscosity; or the pH will be way off. Do not put the strips directly into the product. Even if you are taking the pH of the product directly, you want to add your product into a separate beaker. Wait for the reading to be stable, take a note of the pH, and discard the Sample after. Then put the product on the scale and tare it. Add 0.10g either the 50:50 citric acid solution (to lower the pH), the sodium hydroxide (to raise the pH), or TEA (to raise the pH of the product). Stir well, then wait at least 1 minute before making another dilution. Keep repeating the process until you get the desired pH. You will be surprised how much it may take. I recommend making a bigger batch than you want so you can account for that. Substitutions and Alterations: Substituting ingredients will change the final feel, viscosity, and overall effect of final product. percentages and formulating procedure may need to change with substitutions. These substitution suggestions are just suggestions and have not been tested to work. To find out where to purchase ingredients check out the ingredient suppler page. See notes in the beginning of the post. Sources and References: What to Learn how to Formulate Stable Emulsions?Consider gaining access to the Diamond Level blog. 1 Month Access to Diamond Level

$10.00

Want to be a part of the Diamond Level Blog? Learn to formulate safe and stable cosmetics for you or your business. This is the way to access exclusive content on the website!

You must pay for the month before gaining access. Then I will manually add people. After that, you will be sent an email to set up your password. Once you have created a password, then you can access the content for that month. For testimonials, see this page (Link).

I accept the TERMS AND CONDITIONS by clicking "Add to Cart" and have read the PRIVACY POLICY. Prices are final. No refunds are allowed. 1 Year Access Diamond Level

$119.99

Want to be a part of the Diamond Level Blog? This is the way to access exclusive content on the website! You must pay for it before gaining access. Then I will manually add people. You will be sent an email to set up your password. Once you have created a password, then you can access the content for that year. Two days before your membership ends, I will remind you. 😉

Want to look at all the options? Click Here I accept the TERMS AND CONDITIONS by clicking "Add to Cart" and have read the PRIVACY POLICY. Prices are final. No refunds are allowed.  This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

1 Comment

Zachariah Kovac

5/22/2023 03:45:50 pm

Let me know what you think!

Reply

Leave a Reply. |

Disclaimer!You are at your own risk when making anything from this blog. I am not liable for any mishaps that may occur. I do my best to include everything in the procedure so, that accident are less likely occur! Archives

June 2024

Categories

All

|

RSS Feed

RSS Feed